Micronic

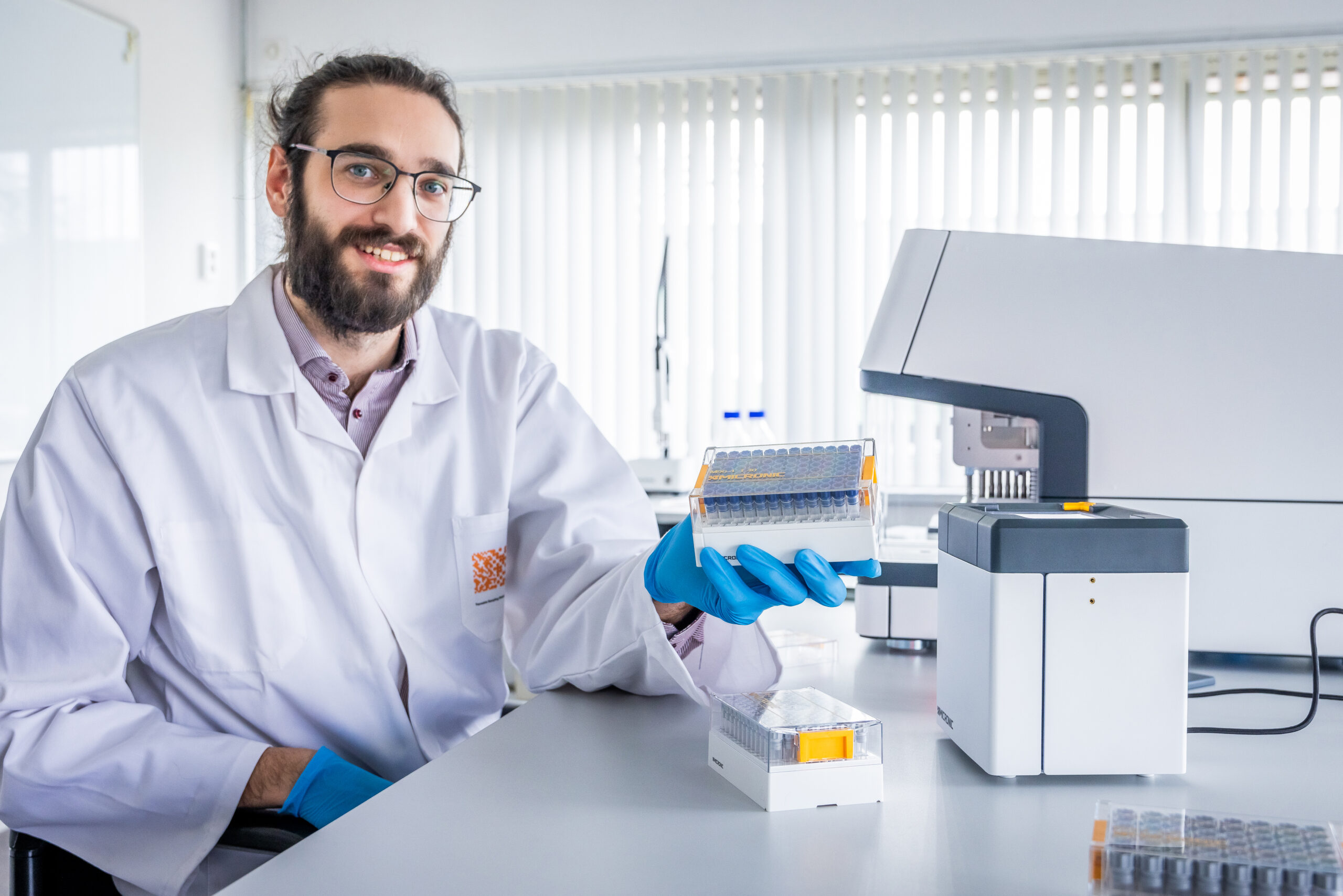

Micronic’s goal is to advance research by serving scientists in finding solutions that contribute to a higher quality of life. We develop and manufacture a range of products to enhance the process of sample preservation and storage.

01 Micronic

02 About Micronic

Innovation in Sample Storage.

Micronic is an independent organization with its headquarters located in Lelystad, The Netherlands. At Micronic, advancing scientific research to enhance the quality of life is our corporate goal and to achieve this we make innovation and quality a priority. We engage in various innovative processes within our organization, like product development and customer-focused lean manufacturing systems, to create new and improved products, solutions, and services that provide radically better customer experiences.

Our premium labware and precision-engineered equipment are developed and manufactured in-house. This core competence gives us the opportunity to offer top-of-the-line products, delivering exceptional quality, reliability, and durability. Above all, we stand behind our solutions and are confident that you will too.

Product portfolio:

Sample storage, sample preservation, sample tracking, sample management

Website:

Facts & Figures.

- $Founded in 1984

- $Certified according to ISO 9001:2015 and ISO 14001:2015

- $NEN-EN-ISO-14644-1 Class 7 certified clean rooms

- $In-house R&D and manufacturing means first-hand high-tech knowledge necessary to quickly adapt to market developments

Core values.

Passion

Excellence

Expertise

Innovation

03 History

Micronic milestones.

1984

Micronic started its business in March 1984 as a manufacturer of blocks, pipette tips and tubes for samples storage and sample handling. In that same year, Micronic set the standard for the 96-format tube rack that became the official SBS format in 1996.

1996

The α-numerical (A1-H12) identification including refill carrier was introduced by Micronic. The α-numerical identification was the world’s first tube identification system.

2000

The Micronic 2D TraXis code and shortly after followed by the 2D Data-Matrix code, were introduced on a 1.40ml tube. With the 2D code identification system, Micronic was the first to answer the market’s need for the unique traceability of stored samples. In the same year, code reading equipment was introduced.

2017

2019

Two of Micronic’s most popular tubes, the 1.40ml and the 4.00ml, have received an ACT label. The ACT label provides critical information on the environmental impact of lab products. The same year the state-of-the-art Tube Handler HT700 was launched.

2024

Micronic introduced the first eco-friendly rack range on the market. These Eco-Friendly Choice (EFC) racks are made of 99% in-house renewed materials, setting a new sustainable standard for sample storage racks.

04 Product portfolio

Product & Services offering.

Sample storage tubes – Micronic offers a complete line of sample storage tubes that fit in the 96-well, 48-well or 24-well ANSI/SLAS standard rack format. The comprehensive range includes tubes with volumes ranging from 0.30ml to 6.00ml which are suitable for the most common laboratory storage applications. The tubes are available non-coded, alphanumeric coded or with a unique 2D Data-Matrix code on the tube bottom.

Sample storage racks – All Micronic storage racks are based on the global recognized ANSI/SLAS standards and provide an easy and automation friendly method to store your sample storage tubes. For each sample storage tube format Micronic offers a robust and user-friendly storage rack. The racks feature a laser etched 1D rack barcode on one side of the rack and for some racks an additional 2D Data-Matrix code on the bottom.

Sample storage caps – Micronic offers the most extensive range of tube capping products, including screw caps and push caps, in the market. All sealing products are available in an industry leading range of colors.

Sample management equipment – To enable fast, accurate and efficient sample identification, Micronic offers an extensive code reader range which consists of single tube scanners and whole rack scanners. The scanners can read coded 24-, 48- and 96-well format tubes. Micronic also offers a wide range of manual and automated capping and decapping equipment. These devices enable significant productivity gains to be made in the opening and closing of multiple sample storage tubes.