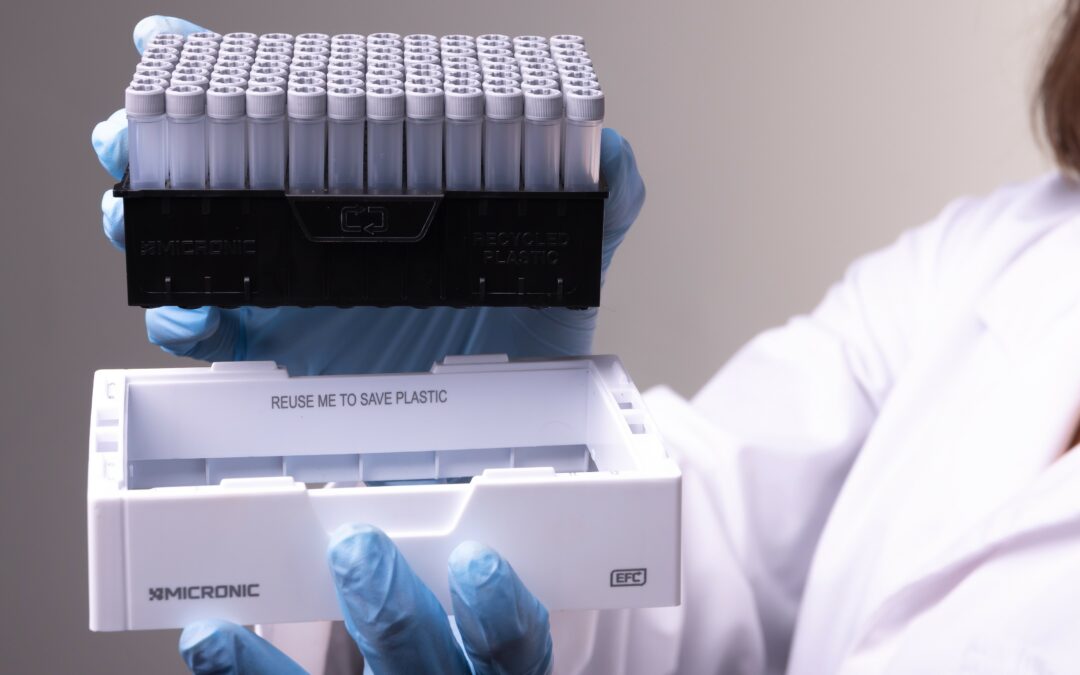

Micronic’s core mission is to advance scientific research that improves the quality of life. This commitment extends beyond innovation in science to their dedication to preserving the environment for future generations. In 2024, Micronic took a significant step toward sustainability by assessing how they could improve the environmental performance of their main production facility in the Netherlands.

Guided by the advice of Horizon Flevoland, the regional development company of the province Flevoland in the Netherlands, they reached out to Energy Expertise Center Flevoland (EEF). EEF developed a comprehensive energy plan, and their valuable insights led to several impactful initiatives designed to significantly enhance the building’s sustainability.

Key Sustainability Initiatives

- Roof Renovation and Insulation

One of the most important steps Micronic took was the complete renovation of their 5,500m² roof. To improve energy efficiency, they upgraded the roof to be super-insulated and fireproof. Proper insulation plays a crucial role in reducing energy loss by retaining heat during the winter and keeping spaces cooler in the summer. Moreover, it supports low-temperature heating systems, further reducing energy consumption. The roof renovation was completed in five months, making it both a substantial and impactful project.

- LED Lighting Upgrade

Micronic made a significant upgrade to their lighting system by replacing almost all the building’s lighting with energy-efficient LED fixtures. Today, 95% of their lighting is LED, which consumes far less energy and has a much longer lifespan than traditional lighting. This not only reduces their energy consumption but also lowers the environmental impact since LEDs convert electricity into light more efficiently and produce much less heat than other types of lighting.

- Efficient Heating Systems

In Micronic’s ongoing efforts to reduce gas consumption, two upgrades were made to their heating systems:

Infrared Heating: The large workshop areas, where transport doors are frequently opened, were previously heated by traditional gas heaters. Now, Micronic uses infrared heating, which directly warms objects rather than the air. This system heats spaces much more efficiently, cutting down energy use and reducing the time needed for heating from about an hour to just three minutes.

Heat Recovery: Micronic also installed a heat recovery system for the building’s air handling units. With substantial ventilation already in place, Micronic now recirculates heat, achieving energy savings of up to 80%. This means that less energy is required to maintain comfortable temperatures throughout the building.

Future Sustainability Plans

Micronic’s commitment to sustainability doesn’t stop here. With pleasant support, expertise, and partial financing from EEF, they have several plans in place for further improvements:

Enhanced Building Insulation: Micronic will continue to enhance the insulation of their production facility by upgrading the facade, skylights, glazing, and frames. These improvements will not only increase energy efficiency but will also enhance the building’s overall appearance.

Solar Panels: Micronic is exploring the installation of solar panels to generate renewable energy. A significant portion of the energy produced will be consumed directly by the building, helping them further reduce their reliance on external power sources. Micronic believes that integrating sustainability into their operations is crucial for both the future of their business and the environment. They are excited to continue making progress on their sustainability journey.